Seminar Program

Bearings

02/05 Development of bearing suppliers and quality control during purchasing

02/06 Basics of bearing technology

02/07 Bearing failures: Investigation and analysis of practical examples

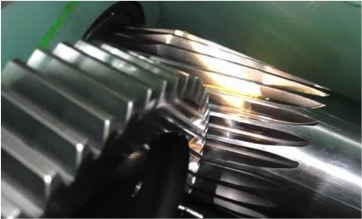

Gearboxes

02/08 Preventive maintenance and condition monitoring of industrial gearboxes

02/09 Supplier development for large industrial gearboxes and quality control 02/09 during purchasing

02/10 Basics of machine acoustics – reduction of noise by design measures

Bearing Seminars

Development of bearing suppliers and quality control during purchasing

5th of February 2018, 10:00 a.m. – 05:00 p.m.

Global sourcing of bearings opens plenty of opportunities for optimization of supply chains. However, any new supplier approval goes along with a certain quality risk. Therefore, this seminar is focused on the following subjects:

- Definition of quality requirements, technical specifications

- Approach during supplier visits and audits

- Requirements related to documentation of production

- Methods for incoming inspection

- Concepts for quality control

Basics of bearing technology

6th of February 2018, 10:00 a.m. – 05:00 p.m.

- Types, Properties, Concepts

- Basics of Tribology

- Raceway crowning

- Material properties

- Sample assessement

Bearing Failures: Investigation and analysis of practical examples

7th of February 2018, 10:00 a.m. – 05:00 p.m.

- Methods for damage investigation

- Damage mechanisms

- Quality characteristics of bearings

- Examples from numerous applications

Gearbox Seminars

Preventive maintenance and condition monitoring of industrial gearboxes

8th of February 2018, 10:00 a.m. – 05:00 p.m.

In many technical systems, breakdowns of particular components lead to enormous subsequent costs as production will be affected significantly. Detection of damages at early stages can lead to minimization of downtime and helps to avoid secondary damages by which overall breakdown costs can be highly reduced. Therefore, this seminar refers to the following topics:

1.Investigation of lubricants

2.Regular inspection and endoscopy

3.Vibration measurement and analysis of obtained results

4.Automation of shutdown in case of detected defect

Supplier development for large industrial gearboxes and quality control during purchasing

9th of February 2018, 10:00 a.m. – 05:00 p.m.

Large industrial gearboxes are typically produced in small series while frequently, individual solutions are requested which require close collaboration between supplier and customer. Here, especially clear communication of requirements, verification of technical concepts and of course the general assessment of production processes are essential.

Accordingly, the topics of this seminar are:

1.Structure and content of technical specifications

2.Verification of technical documents such as drawings, stress and lifetime calculations of shafts, gearings, bearings and housings

3.Approach during supplier visits and audits

4.Requirements related to documentation of production

5.Methods for incoming and production related inspection

Basics of machine acoustics – reduction of noise by design measures

10th of February 2018, 10:00 a.m. – 05:00 p.m.

1.Basics of machine acoustics

2.Excitation forces

3.Structure born noise

4.Noise radiation

You can download the registration form and all the seminar details in order to susbcribe for one or more of the training seminars or contact Ms. Alexandra Becker on [email protected] or call +1 2195105499.

Contact

Elgeti Engineering USA Inc.

Ms. Alexandra Becker

2909 Village Lane #3C

Valparaiso, IN-46383

Phone: +1 2195105499

Fax: +1 2195105685